Most carbon-fibre products are in the lower end of the market and are not highly concentrated in the industry

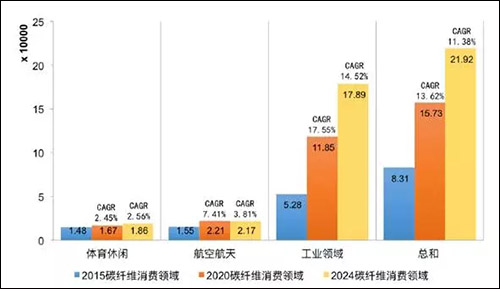

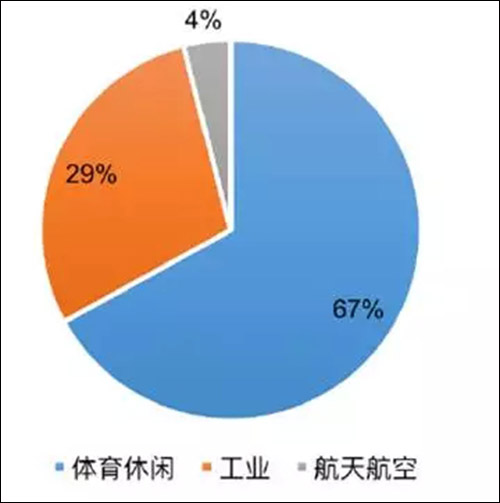

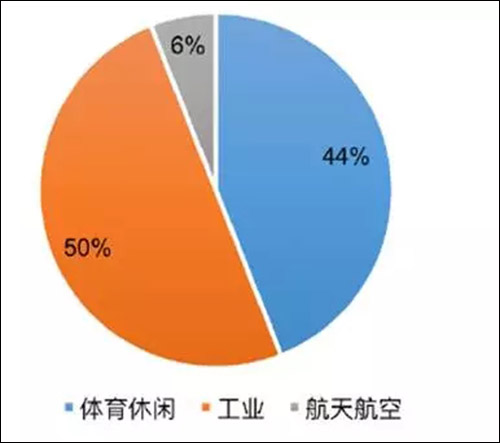

Can be seen from the development of global carbon fiber industry, the aerospace and defense industry is a carbon fiber is the most important application areas, consumption of about 30% of the world total consumption, but accounted for 50% of the world's carbon fiber production; Compared with the development of abroad, carbon fiber market mainly around the sports leisure industry development in our country, accounting for more than 65%, however, the niche market belongs to the low end of the field, very big price competition pressure. At present our country engaged in carbon fiber composite materials research and production unit nearly hundred, but can produce high performance carbon fiber of the aerospace standard enterprise a handful, a large number of enterprises focus in the field of sports leisure, the vast majority of the carbon fiber manufacturers are still in red. With the evolution of the market economy, the carbon fiber industry will face reshuffle, with independent intellectual property rights, and continuous innovation ability of enterprises will be in the future competition.

C. domestic carbon fibre manufacturers lack the core technologies and talents to meet the requirements of high performance carbon fiber in aerospace and high-end civilian areas

The production technology of high performance carbon fiber is complicated, the process is long, the link is more, the subject is more, and the equipment manufacturing ability is closely related. With giant carbon fibers (cf) abroad, compared to decades of continuous accumulation of our country most of the carbon fiber production enterprises lack of mastering the core technology research and development and production personnel, and industrialization of research and development team is not stable, the early stage of the technology and data accumulation deficiency, lack of technology research and development of the laboratory, pilot technology industrialization of amplification, engineering construction of the whole technology experience, thus in preparation, such as quality, cost, equipment and technology with foreign and larger gap. The lack of long-term, stable research and technology teams has become an important constraint on the core competitiveness and sustainable development of the carbon fibre industry.

D. the industrial chain of carbon fiber in our country needs to be further improved

At present, foreign countries have formed the system of carbon fiber composite materials, which is designed, manufactured, analyzed and verified, and applied traction systemically. Like Japan toray heck Selma and the United States have presoak cloth, fabric, short cut fiber, sandwich materials and other intermediate shape, at the same time, directly to provide clients with tailor-made solutions and products, composite materials is convenient for the use of customers, and solve the problem of the carbon fiber products and resin matching.

Because most of the domestic carbon fiber composite materials technology is not mature, lack of corresponding research and development and process support, failed to form a systematic and series of carbon fiber industry chain development model.

(4) the trend of the development of the domestic carbon fibre industry

Carbon fiber industry development space is huge, not only reflected in the defense industry of carbon fiber and the urgent need of strategic emerging industries, but also in the rapid expansion of the national economy every field of application.

The rapid development of the aerospace industry and the deepening of the integration of military and civilian areas provide A development opportunity for the new materials industry represented by carbon fiber

In the long run, China's defense construction lags behind economic development and does not match the rising power status of our country, which is not conducive to stabilizing the complex environment. Commensurate with China's international status at present, the construction of national defense strength, to reform of national defense and the army into the overall situation of national comprehensively deepen reform has risen to national level strategic moves. In recent years, the military and civilian integration has become the overall strategy of economic development and national defense construction, is the power within the period of dream, the motherland's important strategic deployment.

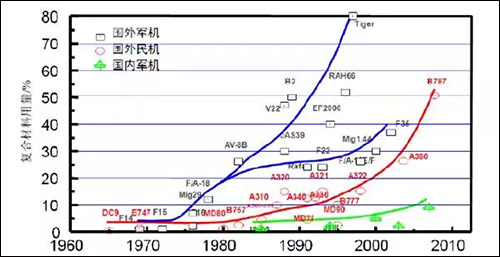

As a new generation of the material basis for the national defense equipment, accelerate the development of new materials technology is an important premise to maintain the leading position of military, carbon fiber composite materials in recent years broader application field and development is very rapid, its use has become a measure of an important symbol of advanced military equipment. In the future, the area of defense construction of carbon-fibre materials will be expanded in the future with the new equipment of national defense and the renewal of existing equipment.

In the aerospace sector, our fighter jets are based on three or four generations of aircraft, and five generations of aircraft have not yet been commissioned, and older aircraft have a higher proportion. According to the international flight data, about 60% of the military aircraft in China is facing a retirement, for fourth and fifth generation fighter for signs of a new generation of combat power, it will promote the demand of military aircraft to a great extent, the development of the military aircraft manufacturing industry provides a rare opportunity, will boost the demand for high-end carbon fiber composite materials.

In the field of conventional weapons and equipment, upgrading of China's weapons is an urgent need to use of lightweight, high strength, corrosion resistance of carbon fiber composite material, has got the attention of related customer, the future market space is huge.

Compared with developed countries, there is a huge demand for domestic carbon fiber, and the development structure will be further optimized

The current domestic civil sports leisure class accounted for the vast majority of the applications of carbon fiber, and in the new energy equipment, rail transportation, civil aviation, engineering construction application, although already started, but application level is low.

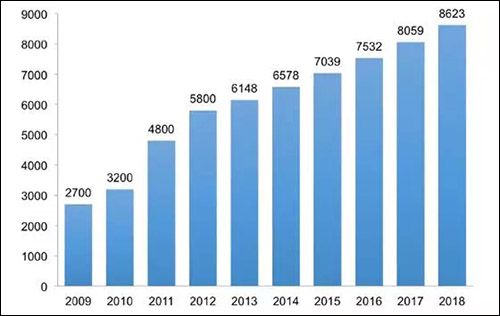

High-speed economic growth, as the national air transport demand, the central and local government increasing investment in civil airport construction, civil airport construction new development climax, greatly promoted the domestic civil aviation industry, the rapid development of passenger demand surge in the number. According to Boeing, China needs 1764 commercial aircraft by 2020, the largest market outside the us. At the same time, the commercialization of large domestic passenger aircraft, which is represented by the C919, provides greater opportunities for the development of carbon fiber in civil aviation.

The future along with the further development of basic industries, the application of carbon fiber in industry scale will improve, important potential market such as wind power equipment, automobile manufacturing, rail transportation and other fields of the future development prospect.

C. under the country's strong support, represented by Jane in science and technology of carbon fibre company, is speeding up the pace of research and development and industrialization, the products and the competitiveness of enterprises constantly improve

From the 70 s that our government began to vigorously support the development of the domestic carbon fiber, "7511" of the meeting organized by general zhang aiping, laid the foundation of national support the development of domestic carbon fiber, through "15", "11th five-year plan", "twelfth five-year" three five-year plans, strong support for the domestic carbon fiber industrialization and application technology research, engineering drawing, make the development of domestic carbon fiber has made great progress. Currently, there are four to five carbon-fibre companies that have been used in the aerospace industry to demonstrate that the T300 technology has been largely passed through. And Jane in the science and technology but also through many years' accumulation of technology, break through the level higher than that of T700 carbon fiber industrialization of engineering technology, production of ZT7 series high-performance carbon fiber has been batch used in the field of aerospace, to break the blockade in aerospace field high-end carbon fibers. In Jane is leading the domestic carbon fiber enterprises of science and technology to achieve higher performance of carbon fiber industrialization pace, using innovative technologies and equipment to reduce the production cost, improve enterprise core competitiveness.